Coating Of Rolls

In continuous galvanizing and aluminizing, a cold rolled steel strip is immersed in a Bath of molten zinc/aluminum alloy.

The steel strip is dipped in the molten bath through a series of rolls, which control the speed and tension of the strip and guide the steel strip through the molten metal bath. The sink roll immerses the strip in the molten alloy, while the stabilizer rolls steer and control the strip before it emerges from the bath.The rolls operating in the molten Zn-Al alloy are sub-jected to a severely corrosive environment and require frequent change and repair. A typical galvanizing shop experiences downtimes on the order of every two weeks to change the rolls. It takes upwards of three days for a complete turn around to resume normal operation. This results in loss of production and profits.

Poor quality of sink and stabilizer rolls can lead to defects in the strip due to:

• Roll not turning,

• Sink roll groove marks appearing on the galva-nized strip,

• Dross buildup on rolls.

Dross The dross particles are formed in the V region where the strip enters the bath, contacts the sink roll and exits the pot. Dross buildup on 316L stainless steel rolls is the result of two chemical reactions:

• Between steel and the galvanizing bath to pro-duce a surface reaction layer,

• Interaction of this layer with dross particles sus-pended in galvanizing bath.Iron in the steel strip reacts with zinc and aluminum in the molten bath to produce dross as per the following chemical reaction: 2FeZn7 (Bottom Dross) + 5Al → Fe2Al5 (Top Dross) + 14Zn(Eq. 1)The dross is picked up by the steel strip and causes a defect.

This is a major quality problem for some galvanizers.Laboratory-scale tests showed that a continuous reac-tion layer between the molten alloy and the roll sur-face provides a favorable position for the buildup of dross particles from the bath. After a longer period.

Thermal spray coating has provided an additional tool to materials engineer to reduce the problems of dross build up, wear, and corrosion of the rolls used in hot dip galvanizing. The molten zinc baths especially with aluminum are aggressive and react with most materials. The life of some of these rolls is very short from two or three weeks. In addition sink and stabilizer rolls experience pick up hard dross particles that could mark the galvanized sheet causing a defect. In order to obtain a reasonable roll life and to reduce dross pick up, continuous strip galvanizers use thermal spray coatings on the rolls. These coatings increase the life of rolls and produce an improved strip surface. Results from research in universities and industrial laboratories are reviewed. Plant trials using a new thermal spray coating based on MoB have given better results with non-wetting of the roll surface and higher roll life compared with coating based on tungsten carbide

- Refurbishment and recoating of rolls and components in steel plants

- The process includes grinding, stress relieving, Tungsten carbide coating, Ceramic coating, chrome plating and finishing processes

- Refurbished more than 2200 steel mill rolls

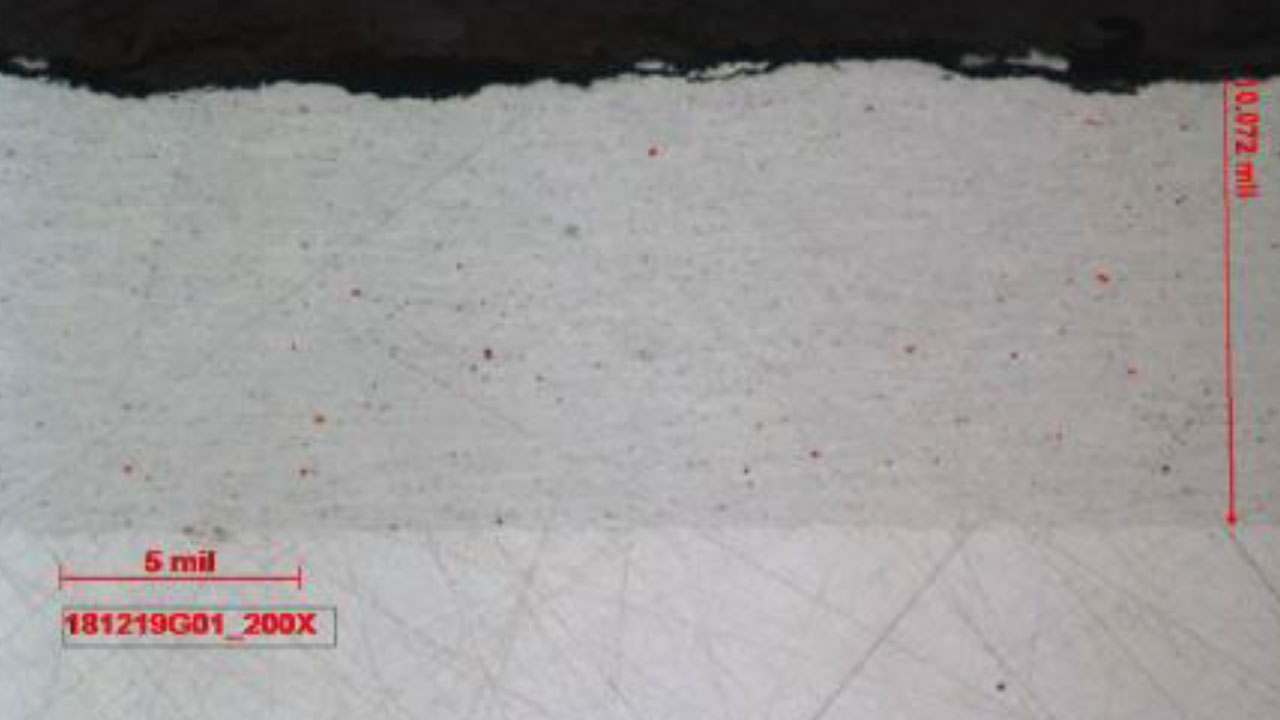

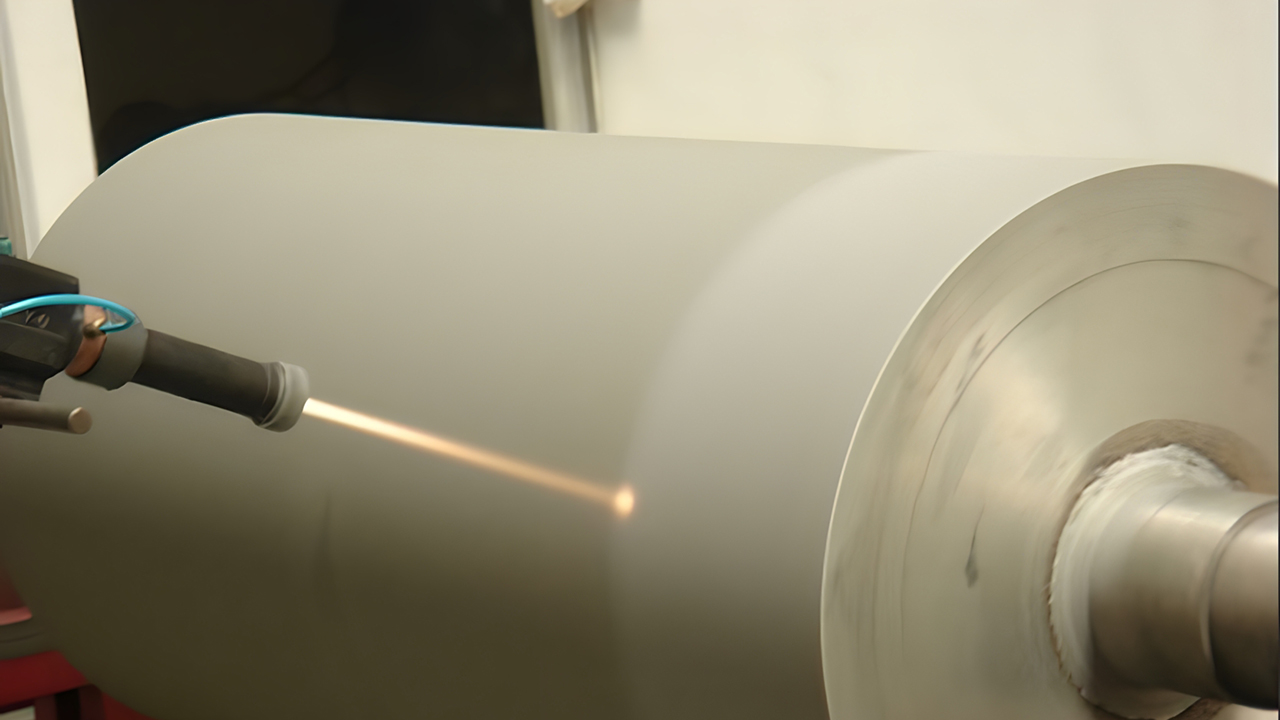

HP/HVOF coating systems mounted on robots are used to provide uniform and very dense Tungsten Carbide and Ceramic base coating on roll surfaces. These coatings are done in an acoustic spray booth.

Thermal Spray Coating

- Applied by High Velocity Oxygen Fuel (HVOF) for Galvanizing and Galvalume

- Applied by air plasma for Aluminizing,

Galvanizing Coatings

- Tungsten Carbide Base

- Additives to reduce wetting to zinc

- Additives for increased corrasion resistance

Galvalume Coatings

- Molybdenum based

- Additives to increase hardness and wear resistance

- Additives for increased corrasion resistance

Aluminizing Coatings

- Full ceramic

- Multi-layer system to improve bonding to roll