Bushes and Sleeves (Ceramic and Cobalt Alloys)

As FOCUS, We have been focusing on projects and the production of wide range of solutions Flat Steel Industry, especially Hot-Dip Galvanizing Lines, regarding; High precision cobalt alloy bushes and sleeves, customized special ceramic bushes by sustaining an exponential growth in the market and offering diversity of specific products for our customers.

Considering this sincere, reliable production and quality system, we are confident in resolving any prerequisites by showing dedication and quality in our work.

Cobalt alloy bushes and sleeves together with ceramic bushes are our main manufacturing focus with various business network connections all over the world by collaboration of talented and dynamic team available in Turkey, Germany and USA.

In the Continuous Hot-Dip Galvanizing Lines(CGL), Sink Roll, Stabilizing Roll and Correcting Roll are used to guide the strip in the Zinc Pot. Bushes and Sleeves installed to the Motor and Operator side of the Sink,Stabilizing and Correcting Rolls are important for the following:

- Maximum wearing resistance at high temperature,

- Compensating angular misalignments, various forces,

- Improving the process efficiency and quality defects,

- Preventing line stoppages,

- Increasing the service lifetime of the zinc pot equipment (Sink Roll, Stabilizing Roll, Correcting Roll).

The Haynes Corp invented the family of cobalt-based alloys more than 100 years ago. Cobalt-based alloys are extensively employed in many industries to address wear resulting from corrosion and thermal conditions.

The purpose of cobalt alloys is the reduce the effect of friction and not lose strength until above 600C. They have corrosive resistance down to 3 PH thanks to the amount of Nickel. The trademark name of “Stellite” belongs to Kennametal as a registered name. Focus Casting and Engineering Co. produces generic alloys with their own names. These alloys tend to be costly, with their pricing primarily determined by the market value of cobalt. The Price policy directly depends on the market price of Cobalt, also the overall expense is affected by the increased complexity associated with the rapid machining of these alloys.

There are no particular heat treatment protocols mandated, aside from those aimed at stress relief. This is due to the fact that the properties of these alloys remain stable and unaffected by heat treatment. Once the alloy has solidified, its characteristics cannot be modified. The propensity of cobalt alloys to fracture or develop cracks limits the application of solid components in numerous instances.

These alloys, including Cobalt Alloy4, Cobalt Alloy6, Cobalt Alloy12 and Cobalt Alloy800 acquire their wear resistance during the transition from liquid to solid in the casting process. The hardness of these alloys is influenced by the quantity and dimensions of the carbides that form during this phase change. The alloying elements, which include iron, silicon, tungsten, and chromium, react with carbon to create carbides. A significant challenge arises from the rapid formation of these carbides, with the duration of this process being contingent upon the thickness of the cross-section of the component. Generally, a thicker cross-section results in a softer material compared to a thinner one. During the transition, while the overall number of carbides diminishes, the size of the individual carbides increases. This leads to an expansion of the inter-granular spaces between the carbides, resulting in a decrease in hardness. In some cases, the carbides may grow to such an extent that they become dislodged from the matrix during the finishing process.

Focus Casting & Engineering Co. specializes in the molding and pouring of cobalt alloys, ensuring that the casting process cools as rapidly as possible. In this context, cobalt serves as the matrix that binds the carbides together, imparting several beneficial properties to the alloys. Notably, the coefficient of friction is exceptionally low, preventing galling.

Bushes and Sleeves manufactured by Focus Casting & Engineering Co. from cobalt alloys provides long lifecysle and stability of work at Continous Galvinizing lines.

Focus Casting & Engineering Co. is consistently prepared to meet specific requirements. Recognizing that their clients are paramount and essential to business success, the company values the patronage of its customers deeply. Furthermore, clients are regarded as integral collaborators in the development of the projects for which they engage Focus Casting & Engineering Co. In the manufacturing sector, the ability to produce highly precise materials and products is of utmost importance to every client.

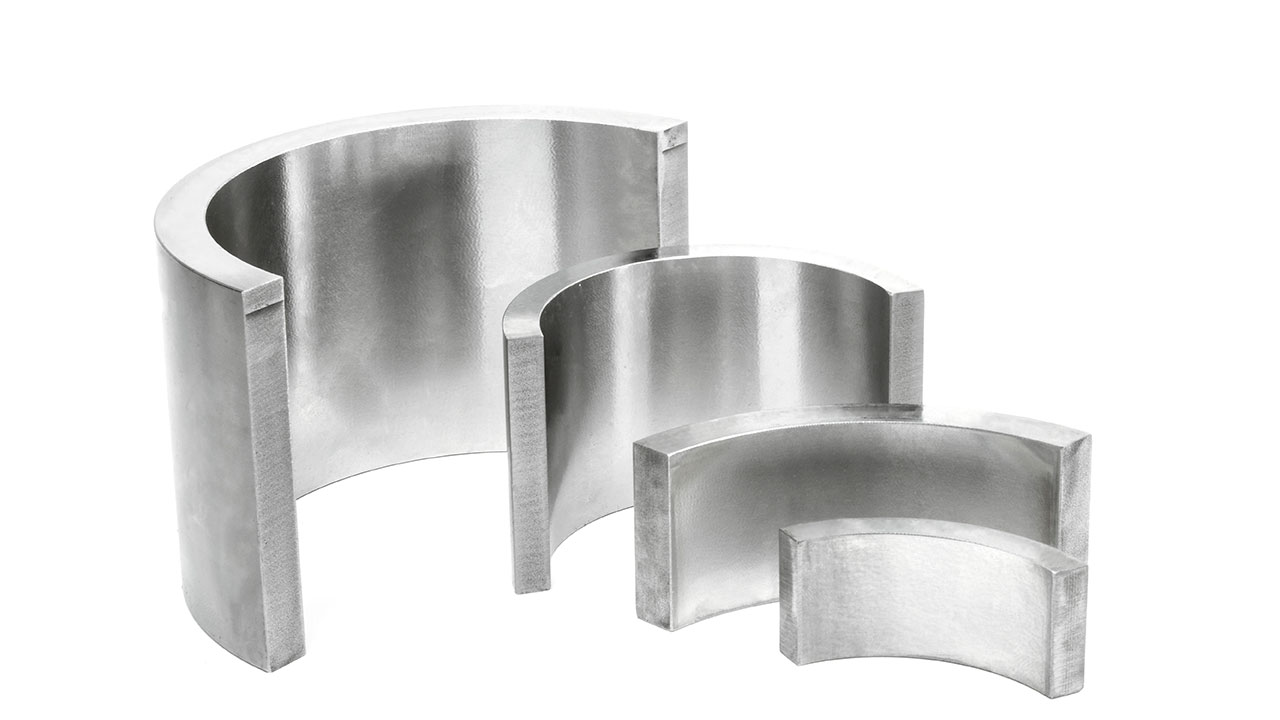

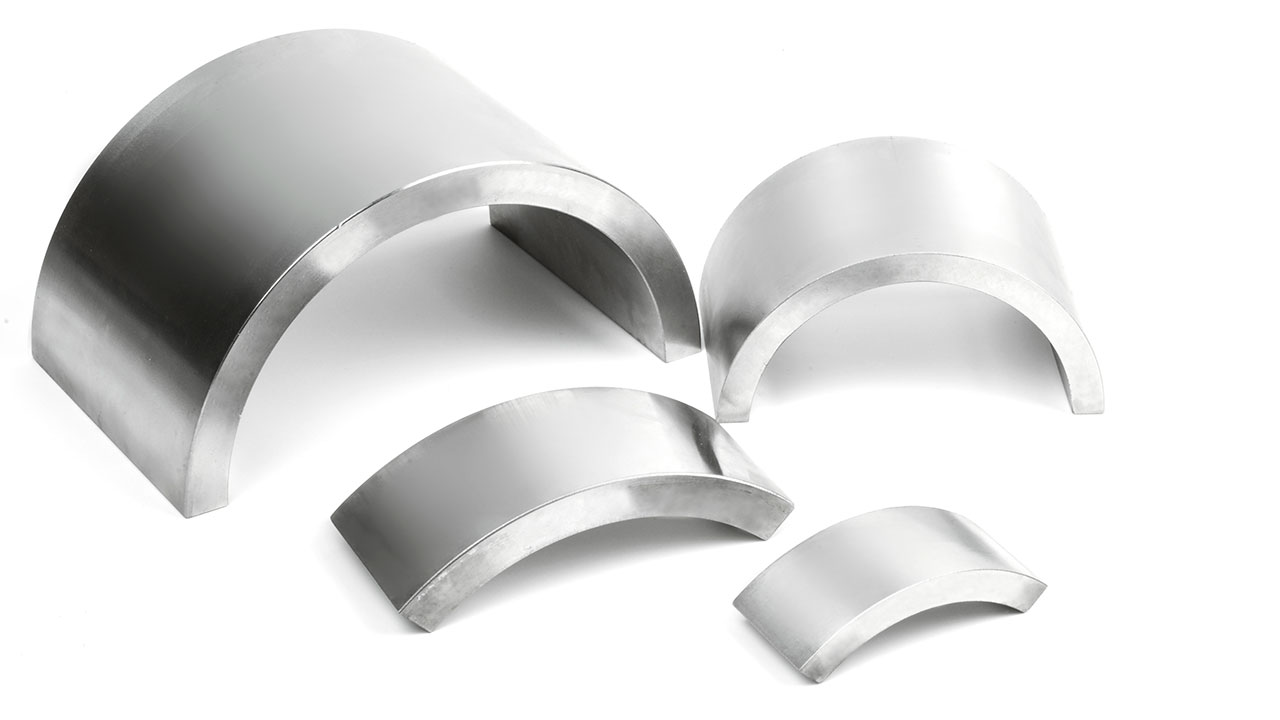

Cobalt Alloy bushes and sleeves, We have produced more than thousands specifications and all of them are produced upon customer’s drawing in order to ensure the excellent wear and corrosion resistance.

Specifications of Cobalt Alloy Bushes and Sleeves are indicated at below table:

|

Material : |

Cobalt Alloy –Grade 3.4. 6.12 etc., Cobalt Alloy T400 and T800 etc. |

|

Process : |

Centrifugal Casting and Coating on Surface |

|

Hardness: |

38-58 HRC |

|

Density : |

8.0 g/cm ³ - 8.4 g/cm ³ |

|

Size : |

Diameter 8-500mm and maxium length 700mm |

|

Properties : |

Wear and corrosion resistance, high temperature resistance |

|

Instructions : |

Drawing made upon cutomers request |

|

Usage : |

Сooperate with other Rolls and Shafts |

|

Tolerance control : |

Turning or grinding surface , tolerance upon drawing |

|

Production lead time: |

Samples in 10 days , normal order 30-45 days |

FOCUS

CERAMIC BUSHES FOR ZINC BATH/CGL LINE

Concerning Zinc Bath in Continuous Hot Dip Galvanizing Line, ceramic bushes from FOCUS are an unbeatable choice. We have been supplying ZrO2+MgO, Si3N4 or any other composition of ceramic bushes/stoppers according to customer requirements.

Here below are some of the advantages of ceramic bushes:

- One of the reasons is ceramic bushes are durable. All materials have their own set of weaknesses. ...

- Ceramic bushings also have excellent thermal conductivity, meaning they dissipate heat quickly,

- Excellent Wear resistance,

- Electrical insulation properties,

- It can resist breaking or cracking when subjected to high temperatures since they are made of dense material with a low melting point,

- They are resistant to corrosion or agressive ambient in Zinc Bath,

- Ceramic bushings also have a longer lifespan than other bushes materials, which makes them a preferred choice for long-term applications.

- Another advantage of ceramic bushings is that they are inexpensive and easy to replace. This makes ceramic bushings an ideal choice for applications where downtime is a concern.

With our more than 20 years of experience in galvanizing line process, not only supplying the bushes and sleeves, but also we can give technical support to our valued customers.